- Food & Beverage/Pharmaceutical

- Energy Saving System

- Wastewater Treatment System

- Water & Environment Plant

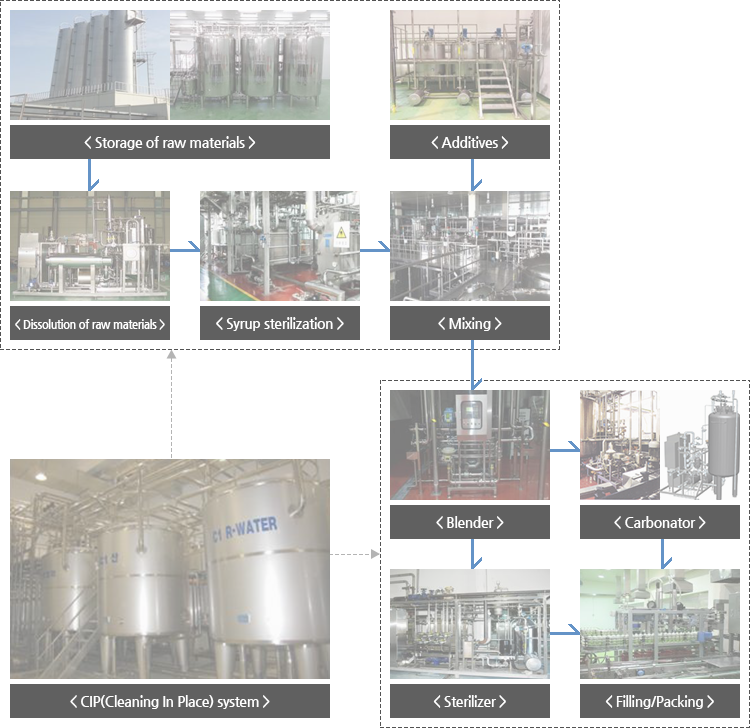

Beverage Plant

We provide turnkey based engineering, equipment manufacturing, installation, commissioning and after-sales service, of the whole system of the beverage, coffee

Major Supply Process

- · Storage/Conveying/Solution of raw materials, Dissolution of additives, Sterilization, Mixing, Blending, Carbonating, Aseptic sterilization, Aseptic tanks, Automatic CIP, Filling, Packaging, Inspection for foreign materials, Stacking/palletizing system

Applied Areas

- · Carbonated drinks, Energy drinks, Sports beverages, Fruit/Extract beverages, Ion beverages, Mineral water.

- · FD instant coffee, Coffee with milk (Canned coffee, Cup coffee)

- · Extract tea (Green tea, Pu-erh tea, Oolong tea, Oriental raisin tea)

Beverage processing plant for carbonated drinks, Juice, Ion beverages and teas

Dairy Products Plant

We provide turnkey based engineering, equipment manufacturing, installation, commissioning and after-sales service of the whole system of the dairy products plant.

Major Supply Process

- · Milk, Processed milk Tank lorry, Raw Milk cooling/clarification, Raw Milk storage, Milk sterilization, Milk standardization, Milk deaeration/homogenization, Surge tank, Filling, Packaging and Automatic CIP.

- · Fermented milk - Raw Milk storage, bag dumping milk powder dissolution, Sterilization of milk powder dissolved in water, Sugar storage, Syrup dissolution, Homogenization/cooling, Cultivation/Fermentation tanks, Mixing tank, Filling, Packaging and Automatic CIP.

- · Cheese - Raw Milk storage, Sterilization/Milk standardization, Curd making, Curd maturation/stretching, Cream sterilization and storage, Whey concentration, Mold/Curing vat, Butter churning, Butter packaging, Cream packaging, Automatic CIP, Inspection for foreign materials Stacking/palletizing system.

Applied Areas

- · Milk, Processed milk, Sterilized milk, Reconstituted milk and Condensed milk.

- · powdered/liquid formula.

- · drinking yogurt, stirred yogurt, yogurt beverage

- · Butter, Cream, Whey product, Ice cream.

- · String cheese, Solo Latte, Slice cheese, Haloumi, Mozzarella

Storage system of powder and liquid materials

bag-dumping

bag-dumping Oil Storage

Oil Storage Concentrates storage

Concentrates storage

We provide turnkey based engineering, equipment manufacturing, installation, commissioning and after-sales service of the system that raw materials are not contaminated or physically changed due to transportation and long-term storage, considering characteristics of powder and liquid materials in the Food& Beverage/Dairy Products Plant.

Major Supply Process

- · bag-dumping, Tilting system for tank lorry, Thawing system, Chopper, Crusher, Air/Conveyer transportation of powder, Transportation of liquid, inspectionvision system, Powder/Liquid raw material storage, concentrates storage, dust collector, Blower, etc

Applied Areas

- · fructose, Oligosaccharide, Honey, Starch syrup, Fruit concentrates

- · Storage of additives, oils and milk fat

- · Storage of raw milk and milk formula

- · Storage of green beans

Sugar Silo & Continuous Sugar Dissolving system

Sugar Silo

- To prevent sugar clumps which can be made when transporting sugar, storing it in and releasing it out of a silo, we provide system reflected by hygroscopic property and physical characteristics of sugar.

- · Major Supply System: Dilute phase conveying system, Dense phase conveying system, Dehumidification system, Sugar silo, Conveyor

Continuous Sugar Dissolving system

- We provide the Continuous Sugar Dissolving system installed at a minimum area which can simultaneously implement sugar dissolution and sugar syrup transportation and control correct sugar contents by automatically controlling input of sugar and purified water.

- · Major Supply System: Sugar hopper, Conveying system, Heat exchanger, Density sucrose solution, solution tanks, Filters

Sugar Silo

Sugar Silo 사이로 하부 이송설비

사이로 하부 이송설비 연속식 설탕용해설비

연속식 설탕용해설비

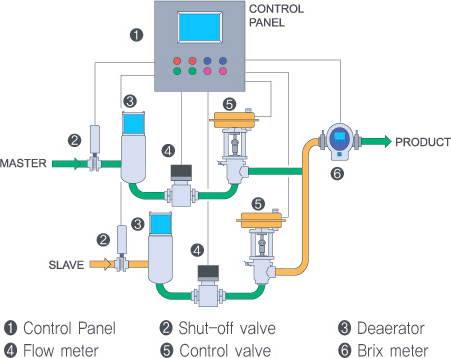

Hanmix Continuous Blending System

The Hanmix Continuous Blending System directly mixes more than two kinds of raw materials in a pipe.

It enables a precise manufacture by using a high precision flow meter and Q.C instrument (Density meter/Density sucrose solution) during the procedure to mix products,

and it can manufacture the products of concentration you want by checking the concentration of mixed products in a pipe and giving feedback into production.

By monitoring and recording production quality through online QC, it maximizes uniform quality and yields.

The Hanmix Continuous Blending System which does not need a mixing tank can save an installation area and reduce automatic CIP time. The equipment also maximizes the operation ratio as it can use various mix proportions by saving them.

연속식 혼합설비는 혼합탱크가 필요하지 않아 설치 공간 절약 및 자동 CIP 시간을 단축할 수 있으며, 하나의 설비에 다양한 배합비를 저장하여 사용할 수 있으므로 설비의 가동률을 극대화 할 수 있습니다.

Applied Areas

- · Dairy Products: Liquid fermented milk, Processed milk, etc.

- · Beverages: Fruit juice, Ion beverages, Carbonated drinks, health drink, etc.

- · Liquors: Beer, Fruit wine, Soju, Whiskey, Cocktail, etc.

Operation Principle

The Hanmix Continuous Blending System is composed of two controllers: One is a sugar content (or density) controller and the other is a flow (ratio) controller.

The system controls sugar contents (or density) to avoid sudden change in purified water or an undiluted solution by controlling the flow of the slave according to the flow of the master.

When exceeding the set density, the sugar content (or density) controller reduces the set value of the flow controller

and the flow controller reduces valve output to have the density reach the set value.

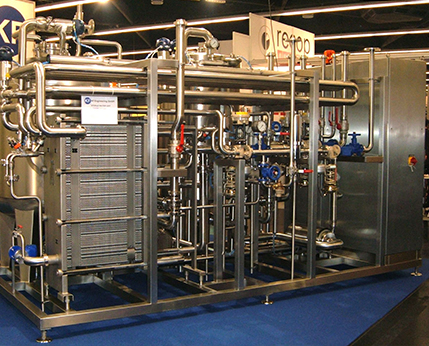

Sterilization System

We provide the latest system which can operate full automatic sterilization systems (LTLT/HTST/UHT) and minimize degradation of products by high temperature of Plate/Tubular type Heat Exchangers according to physical characteristics of sterilization products.

Plate Type

Plate Type Tubular Type

Tubular Type

Applied Areas

- · Dairy Product Industry: Milk, Soy bean milk, Cream, Skim milk, Cheese, Whey, Yogurt, Ice cream, etc.

- · Beverage Industry: Wine, Fruit juice, Non-alcoholic beverages, Extract beverages, Beer, Sugar Syrup, Fruit extracts, Coffee extracts, etc.

- · Bakery Industry: Jam, Cream, Chocolate, Yeast, Pudding, etc.

- · Food Industry: Mayonnaise, Ketchup, Tomato condensate, Oil, Soup, Honey, Whipping cream, etc.

- · Pharmaceutical Industry: Desalted water, Sterile water, Detergents, etc.

Aseptic System

Aseptic system is aimed for maintaining the quality stability of products prone to go bad from storage and distribution process of completed goods. We provide systems for eliminating microorganisms in products and blocking contract with airborne bacteria.

Major Supply equipment: : Aseptic UHT system, aseptic tank, aseptic valve cluster, barrier module, air filtering system, steaming system, homogenizer, deaerator

Aseptic UHT system

Aseptic UHT system Aseptic 및 Barrier 모듈

Aseptic 및 Barrier 모듈 균질기, 탈기기

균질기, 탈기기

Application Area

- · Tea industry: Infusion tea, Grain tea, etc.

- · Dairy industry: Products containing milk such as protein powder and coffee

- · Beverage industry: Neutral beverage, Sport drink, juice, juice with pulps, etc.

Cleaning In Place System – Automatic CIP System / SIP System

Automatic CIP (Cleaning In Place) system aims for eliminating micro impurities that cannot be identified visually and eliminate all microorganisms as well as visual pollutants from the surface of production equipment.

Production line and injection line are automatically cleaned by using cleaning agents without disassembling the equipment, and cleaning verification is performed by conductivity level.

We supply the optimum automatic CIP system that prevents pollution of product, stabilizes quality, improves sanitary level, saves work time, extends euqipment lifetime and improves productivity by providing the satisfactory cleaning and aseptic effects at all times.

Single use 자동 CIP system

Single use 자동 CIP system Re use 자동 CIP system

Re use 자동 CIP system

Application Area

- · Dairy industry : Milk, soy milk, cream, skim milk, cheese, whey, yogurt, ice cream, etc.

- · Beverage industry : Wine, fruit juice, non-alcoholic beverage, extract beverage, beer, RTD coffee, etc.

- · Bakery industry : Jam, cream, chocolate, yeast, pudding, etc.

- · Food industry : Mayonnaise, ketchup, concentrated tomato paste, oil, soup, honey, whipping cream, etc.

- · Pharmaceutical industry : Pharmaceutical products

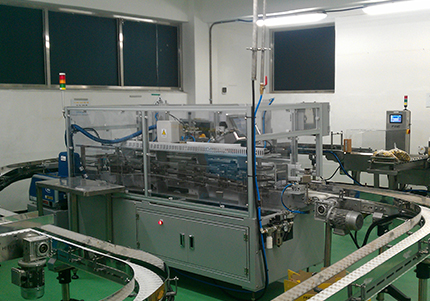

Automatic Packaging & Filling System

We supply the turn-key base system including engineering of packaging equipment, and production, installation, commissioning and after service on system for filling, packing, conveying, palletizing and raw material supplying.

Filler & Sealing

Filler & Sealing

-

System for filling, capping or sealing product into empty (plastic or glass) bottle

- - Filling method : vertical, rotation

vertical - Low capacity, Rotation – High capacity - - Applicable products: Liquid products

Pouch Filler

Pouch Filler

-

equipment for filling and sealing product into a pouch

- - Filling method : Series, rotation

Series – High capacity, Rotation – Low capacity - - Separate dust collection, equipment for scatter prevention may also be used for filling powder products

- - Applicable products: Liquid/powder products

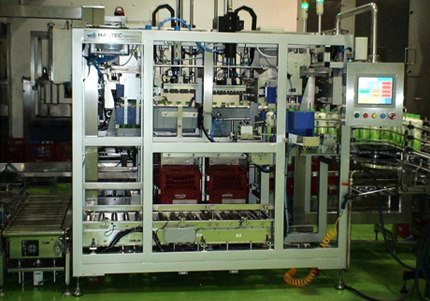

Carton Case Packer

Carton Case Packer

-

Equipment for packing prepackaged products in sticks or pouches in small boxes

- - Capable of small box packing of various sizes with one machine

- - Double-sided packing method

- - Used for small volume (10, 20, 30, 40, 50 pcs)

Upper Sealer

Upper Sealer

-

Equipment for packing prepackaged products in sticks or pouches in medium sized boxes

- - Capable of medium box packing of various sizes with one machine

- - Top packing method

- - Used for large volume (100, 120, 150, 180, 200 pcs)

Palletizer

Palletizer

-

Equipment for automatic stacking of products onto pallets

- - Composed of diverter, roller/chain conveyor and magazine

Depalletizer

Depalletizer

-

Equipment for supplying containers stacked on pallets layer by layer onto conveyor

- - Capable of installing equipment for collecting empty pallets and removing liners

- - Composed of roller/chain conveyor and magazine

Case Packer

Case Packer

-

Used for packing prepackaged products in cans, bottles or cartons in box

- - Major supply equipment method: Wrap-around type, set-up type

- Wrap-around case packer – Pushing in products into set-up box

- Set-up case packer: Covering products with box

Crate Case Packer

Crate Case Packer

-

Used for loading PET or PE products onto crate

- - Mainly used in dairy product packaging line

Testing Equipment

Metal Detector

Metal Detector

-

Testing equipment that detects by qualitatively analyzing metals or impurities in products by using magnetic field after packaging

- - Detection capacity: Metals, etc.

Weight Checker

Weight Checker

-

Testing equipment that grades products by weight by measuring the weight of product after packing

X-ray

X-ray

-

Testing equipment that detects by qualitatively analyzing metals and impurities by using x-ray in product after packaging

- - Detection capacity: Metals, aluminum, plastic, etc.

Vision system

Vision system

-

Testing equipment for expiry date and barcode inscribed on product by using camera after packaging

Conveyor

FLEX C/V

FLEX C/V

- - Applicable products : Conveying and buffering of packaged small volume products, small boxes and medium sized boxes

BELT C/V

BELT C/V

- - Applicable products : Conveying of raw materials (fresh beans, red ginseng, tea, cheese, etc.) and packaged products (coffee sticks, cartons, pouches, medium sized boxes, etc.)

Roller C/V

Roller C/V

- - Applicable Products : Conveying and buffering of heavy products, drums, large boxes, etc.

Pallet C/V

Pallet C/V

- - Applicable products : Conveying of loaded pallets and empty pallets

Robot System

Robot

Robot

-

Capable of loading various products from boxes to crates according to the grip of robot that loads packaged products onto pallets by using multi-legged robot

- - Applicable products: Applicable to almost everywhere due to free radius of action. Suitable for heavy product loading line (drums, crates, boxes, etc.)

Delta Robot

Delta Robot

-

Equipment for conveying packaged products to desired area by using delta robot

- - Applicable Products: Suitable for production line for small volume product due to quick movement (vinyl pouches, small volume product line work, etc.)